Bridge Report:(1433)BESTERRA The Fiscal Year Ended January 2025

President Yutaka Honda | BESTERRA CO., LTD (1433) |

|

Company Information

Market | TSE Prime Market |

Industry | Construction business |

President | Yutaka Honda |

HQ Address | Kiba Park Building, 3-2-6 Hirano, Koto-ku, Tokyo, Japan |

Year-end | End of January |

Homepage |

Stock Information

Share Price | Share Outstanding (End of the term) | Market Cap. | ROE (Act.) | Trading Unit | |

¥988 | 8,990,200 shares | ¥8,882 million | 9.2% | 100 shares | |

DPS (Est.) | Dividend Yield (Est.) | EPS (Est.) | PER (Est.) | BPS (Act.) | PBR (Act.) |

¥30.00 | 3.0% | ¥101.57 | 9.7 x | ¥546.88 | 1.8 x |

*The share price is the closing price on March 25. Share outstanding is from the financial results for the fiscal year ended January 2025.

Consolidated Earnings

Fiscal Year | Net Sales | Operating Income | Ordinary Income | Net Income | EPS | DPS |

Jan. 2022 (Actual) | 5,966 | 488 | 721 | 1,391 | 165.48 | 16.00 |

Jan. 2023 (Actual) | 5,458 | -215 | -94 | -64 | -7.33 | 20.00 |

Jan. 2024 (Actual) | 9,394 | 246 | 407 | 231 | 26.08 | 20.00 |

Jan. 2025 (Actual) | 10,897 | 373 | 592 | 409 | 46.25 | 20.00 |

Jan. 2026 (Forecast) | 13,000 | 1,200 | 1,280 | 900 | 101.57 | 30.00 |

* The forecasted values were provided by the company. Unit: million yen. Net income is profit attributable to owners of parent.

This Bridge Report introduces the earning results for the fiscal year ended January 2025 and other information of BESTERRA CO., LTD.

Table of Contents

Key Points

1. Company Overview

2. Fiscal Year Ended January 2025 Earnings Results

3. Fiscal Year Ending January 2026 Earnings Forecasts

4. The medium-term management plan, “Action Plan for Decarbonization 2025”

5. Conclusions

<Reference: Regarding Corporate Governance>

Key points

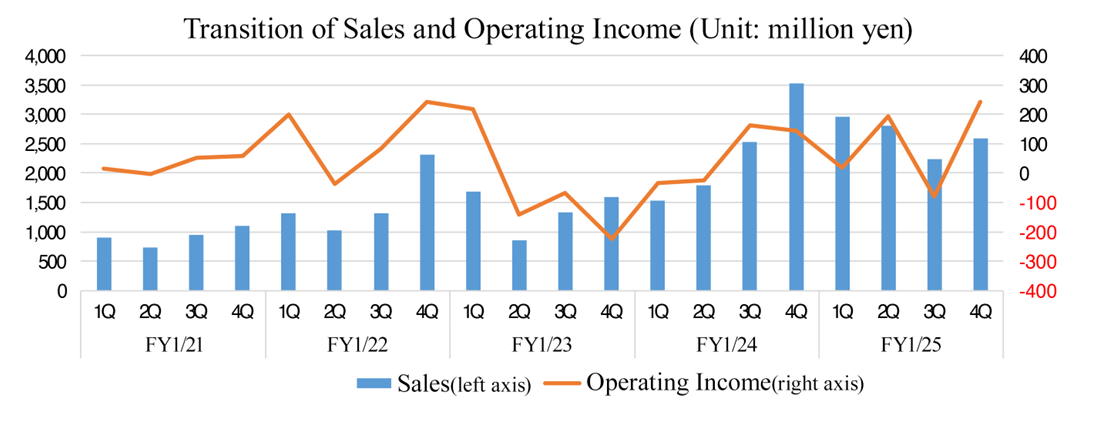

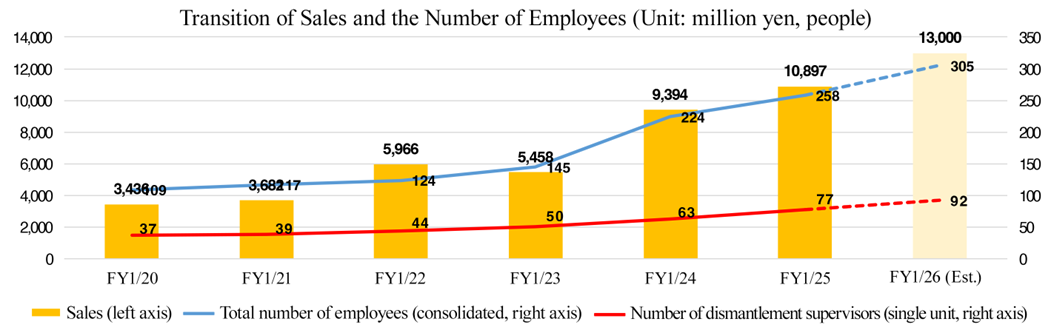

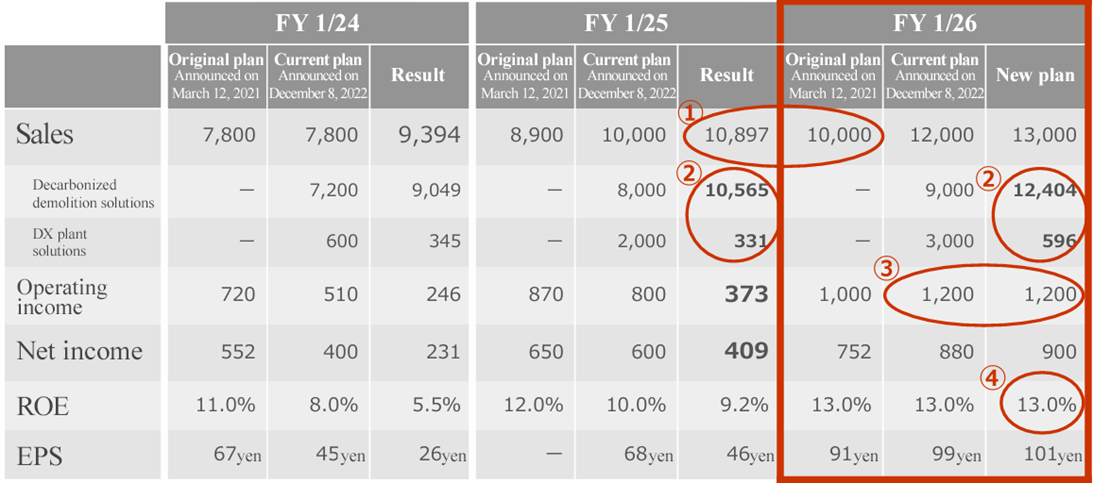

- In the fiscal year ended January 2025, sales grew 16.0% year on year to 10,897 million yen. The backlog of orders, including those for long-term large-scale projects received in the previous fiscal year, was ample, and the order receipt environment was favorable. In addition, the recruitment of personnel, which had been a bottleneck, was favorable, so their organizational structure was fortified, and plant demolition projects progressed smoothly. As a result, sales hit a record high. Operating income rose 51.3% year on year to 373 million yen. The profits of consolidated subsidiaries were sluggish. However, Besterra’s plant dismantlement business, which is the mainstay, recorded a record-high profit of 577 million yen, as the company made efforts to shorten demolition periods by exercising their ingenuity in designing demolition methods and process management. Sales and profit grew considerably, but they fell below the forecasts disclosed in September. The company paid a year-end dividend of 10 yen/share as forecast for a total of 20 yen/share per year.

- For the fiscal year ending January 2026, sales are expected to grow 19.3% year on year to 13 billion yen and operating income is projected to rise 221.2% year on year to 1.2 billion yen. The company will actively make efforts to receive orders for large-scale projects, which are expected to produce profit stably, manage costs thoroughly, and secure personnel. In addition, order backlog is at a high level, and the company will make continuous efforts to receive orders for plant demolition. The company upwardly revised the target sales set in “Action Plan for Decarbonization 2025” from 12 billion yen to 13 billion yen. In terms of profit, the company will try to stabilize profit by increasing sales, actively recruit construction personnel, and improve the precision in price estimation and cost management by utilizing IT technologies, including AI. While selecting and concentrating on specific businesses, The company will consider the integration, discontinuation, or sale of some businesses. Regarding dividends, the company plans to pay a total of 30 yen/share (including an interim dividend of 15 yen/share) per year, up 10 yen/share from the previous fiscal year. The expected payout ratio is 29.5%.

- In the fiscal year ended January 2025, it seems that Besterra faced a significant turning point. While sales have been growing, the company strove to earn profit through trial and error while having some unprofitable projects, as an operating loss was posted in the fiscal year ended January 2023. In the fiscal year ended January 2025, group companies struggled, so profit seems to be low, but the performance of the plant dismantlement business improved significantly. In the fiscal year ending January 2026, the company will try to shore up group companies while continuing efforts to improve sales and profit margin of the plant dismantlement business. Accordingly, profit is projected to rise considerably.

- Regarding the seemingly audacious goal of achieving “sales of 100 billion yen and an operating income of 10 billion yen,” President Honda commented, “It seems to be more feasible.” This comment makes him more dependable. Although it was challenging to secure sufficient manpower, the company has recruited the largest number of dismantlement supervisors in their history, to overcome the issue. It seems that the development of an organizational structure for dealing with significant sales growth is progressing as the company is recruiting personnel steadily. Since assuming the post of president in 2023, President Honda has conducted various investments, and it is time to see their outcomes. Sales are growing significantly and profit margin is improving, but the reflection of them in share price is delayed. If improvements become evident, share price will probably increase accordingly. We would like to pay attention to the quarterly progress.

1. Company Overview

As a specialist in plant dismantlement, BESTERRA manages the dismantlement of plants (metal structures) for iron-making, power generation, gas, petroleum, etc. Its core competence is “the method and technology for dismantling plants,” and it has many patented methods including international patents. The company concentrates its managerial resources on engineering (proposal, design, and work planning) and management (supervision and work management), and outsources actual dismantlement work to its affiliates, and so it does not own heavy machinery or construction teams (the risk of owning assets can be avoided), and it is unnecessary to procure materials, etc. and make transactions for material production (the inventory risk can be avoided).

In addition to the company, the group has acquired Hiro Engineering, which provides human resource services for design work, etc., 3D Visual KK, which handles 3D scan modeling and design work, and Yazawa Co., Ltd., which owns advanced technologies for removing asbestos as consolidated subsidiaries. Additionally, in August 2023, the company has also acquired Oda Corporation Co., Ltd., which mainly maintains work and main frame construction work, and its subsidiary, TOKEN Co., Ltd. as consolidated subsidiaries. As of the end of January 2025, there were five consolidated subsidiaries.

The corporate name “BESTERRA” was coined by combining the English word “Best (the superlative of ‘good’)” and the Latin word “Terra (the earth),” and infused with the ambition to “create the best earth.” By developing an integrated system for dismantling and recycling, the company aims to actualize an advanced recycling society and contribute to the earth environment.

1-1 Corporate ethos and the code of conduct

Under the corporate philosophy of "we will contribute to the global environment with flexible thinking, creativity, and techniques," the company's mission is to "realize the BEST (highest) TERRA (earth)" and "contribute to the development of an advanced recycling-oriented society (development of vein industries).”

The company has also established a "Basic Sustainability Policy" to contribute to the realization of a sustainable society.

◎ Basic Sustainability Policy

We, Besterra, are committed to both "realization of an advanced recycling-oriented society" and "sustainable corporate growth" based on our corporate philosophy of "We will contribute to the earth environment with our flexible way of thinking, creativity, and technologies using these concepts."

1-2 Characteristics of the business

The company has a single segment consisting of demolition and maintenance business. For others, it engages in the human resource service business and the 3D scan, modeling, and design business. In the fiscal year ended January 2025, demolition and maintenance business accounted for 97.2% of total sales.

Demolition and maintenance business

In the demolition and maintenance business, the company works mainly on all types of plants in the fields of ironmaking, electric power, gas, petroleum, and petrochemicals, etc. The company offers services on overall engineering processes including proposals, designing, work planning, outsourcing/arrangement of equipment and materials, supervision, safety management, cost management, financial management, and handling of governmental procedures. It focuses on designing its unique demolition technologies and supervising demolition works based on demolition plans and uses specialized subcontractors for demolition works. The clients for plant dismantlement are leading companies that own plants for ironmaking, electric power, gas, petroleum, etc. In most cases, the equipment installation companies of the corporate groups of clients or leading general contractors are entrusted with dismantlement, and then BESTERRA serves as the primary or second-tier subcontractor.

Also, in the plant dismantlement business, BESTERRA receives valuable materials generated through dismantlement, such as scrap, and sells them to scrap handlers. Accordingly, the company estimates the value of valuable materials while comprehensively considering the material, quantity, price (market price of each material, such as iron, stainless steel, and copper), etc. and negotiates with clients about the fee for dismantlement work. In accounting, the gain from sale of valuable materials is included in revenue from dismantlement work and posted as part of sales from completed dismantlement work. In some cases, contractors (clients) dispose of (sell) scrap, etc. by themselves.

Furthermore, Oda Corporation Co., Ltd. and TOKEN Co., Ltd., which became consolidated subsidiaries in August 2024, will be part of the demolition and maintenance business, with maintains work and main frame construction work for various plants as their core business.

*Two standards for posting revenue and seasonality of revenue posting of the company

The standards for posting revenue from contracts can be classified into the completed contract method, in which revenue is posted when works are completed, and the percentage-of-completion method, in which revenue is posted according to the progress of works. The company basically applies the percentage-of-completion method to large-scale projects whose period exceeds 3 months from the fiscal year ended January 2023 (the completed contract method is applied to projects that do not meet the aforementioned criteria). The timing of posting revenue (the completion of demolition work) from works for which the completed contract method is used is often affected by the capital investment plans of clients. In the case of BESTERRA, revenue tends to be posted in the first quarter (February to April) and the fourth quarter (November to January) (the seasonality of revenue posting). However, the variation in quarterly performance may mislead investors, so the company is expanding the scope of application of the percentage-of-completion method step by step, to equalize the timings of revenue posting.

Others

In response to the chronic shortage of skilled construction workers, the company began providing human resource services in January 2013, and in March 2018, it made Hiro Engineering, which handles human resource services such as design work, a subsidiary. In January 2015, the company began offering a 3D measurement service as well. It established 3D Visual KK in December 2019, and 3D scan modeling and design business was transferred from INTER ACTION Corporation (securities code: 7725) in February 2020.

1-3 Strengths: an excellent client base, efficient dismantlement management based on plenty of experience, and intellectual property, such as patented methods

The strengths of the company are excellent client assets, efficient dismantlement management based on plenty of experience, and intellectual property, such as patented methods. The clients are basically engineering subsidiary companies of leading companies in ironmaking, electric, gas, coal oil fields, and major general contractors, which are excellent clients with no credit concerns. The clients of the leading companies highly evaluate the company’s total management (low cost and high efficiency) of plant dismantlement that it cultivated experiences for over 40 years. Another strength is the various technologies and know-how that the company has accumulated through environmental protection construction projects, etc., which have become its actual and potential intellectual property, including the recycling of waste materials.

The company operates business under the concepts of "unbreakable by its creators (new ideas)," "the only one company specializing in plant dismantling," and "asset-light management.”

Patented methods, etc.

“Apple peeling demolition method” and fusing robot “Ringo☆Star”

The “apple peeling demolition method” is a method of dismantling a large spherical tank, such as gas holders and oil tanks, by cutting it in spirals from the center of the ceiling of the enclosure part. The cut part spirals down to the ground gradually under the force of the earth’s gravity (natural energy). The method enjoys superiority in a work period, cost, and safety, and has considerable competitive advantages, realizing “greater promptness, higher cost efficiency, and added safety.” Furthermore, the company offers a robot for the fusing process, “Ringo☆Star,” which automates the “apple peeling demolition method.” (The company is also working to expand the range of applications for “Ringo☆Star” by developing a new attachment).

Environment-related methods

The company has cultivated experiences and business results of a multitude of environment-related demolition works, using the “fireless methods” which do not require the use of fire. For example, although polychlorinated biphenyls (PCBs) are considered as a toxic substance and therefore totally abolished today, it had been used for many years in transformers and condensers because of its excellent thermal stability and chemical stability (electric insulation characteristics). In many cases, transformers and condensers are disposed of in conjunction with plant demolition works; however, because PCBs gasify when they are treated at the high temperature, posing a risk of inhaling the gas so generated, any firearms (such as gas cutting machines) cannot be used in demolition and withdrawal involving PCBs. The company is skillful at fireless and quasi-fireless methods using saber saws (which cut off objects with their saw blades moving in a reciprocating manner) that can cut off objects thicker than the thickness, which, in the industry, had been considered impossible to cut, through numerous devices, including measures against seizure of motors and recycling of blades. BESTERRA has applied for joint patents with Hitachi Plant Construction, Ltd. for a transformer dismantling method, a transformer dismantling jig, and a cutting device for dismantling a transformer.

Windmill demolition works

The number of power-generating wind turbines continues to increase by about 20% annually worldwide, but the demand for dismantling is expected to increase in the future due to wear and tear and economic obsolescence. According to the company's data, the global wind power generation amount has continued to grow at an annual rate of about 20%, reaching 486,790 MW (about 340,000 onshore units and about 4,000 offshore units). In Japan, there were 2,574 wind turbines as of the end of 2021, mostly onshore, but the trend is shifting toward offshore wind power. Meanwhile, as the useful life is approximately 15 to 20 years, and the windmills for power generation established in the early stage are reaching the application limit. Moreover, not a few plants need to be dismantled due to damage or fatal failure caused by thunderbolts or typhoons.

How to knock down a power-generating wind turbine (international patent application)

Dismantling of windmills is usually done using scaffolding erected on the outside of the supports. As some windmills have been built in mountain districts and on the sea, demolition of them is highly difficult. The company has devised a method for dismantling wind turbines that does not require scaffolds and has already acquired a domestic patent for “Method of knocking down a power-generating wind turbine.” International patents are pending for “Method of knocking down towering structures using their bases” and “Method for dismantling tower-shaped equipment for wind power generation.” Safety of workers can be improved dramatically, and the work period can be shortened by using these patent-based methods.

Pursuit of the value of the 3D business

Using services such as layout simulation, strain/bending/torsion measurement, comparison of structures before and after improvement, and video walkthroughs, the company converts physical data taken when plants were established (more than 30 years ago) into the latest 3D data and uses that to provide detailed information about the dismantling process. They also provide unique 3D measurement services for dismantling work using the latest measuring technology and simulation systems that are capable of drawing data as 2D diagrams, handling BIM/CIM modeling, Perfect 3D, and 3D printing, etc.

“Visualize” the dismantling process

Layout simulation | The equipment models produced with 3D CAD are placed in 3D data, and the replacement of equipment can be simulated. By moving the equipment models, it is possible to check how they interfere and collide with one another. |

Strain, bending, and torsion measurements | It is possible to measure changes in shapes. This is useful for diagnosing frameworks tentatively, to check whether a building got distorted due to an earthquake, deterioration, etc. |

Comparison of structures before and after installation

| The shapes of equipment that changes due to heat and vibration, such as pipes, conveyors, and furnaces, at the time of installation and after operation are compared. With 3D data, it is possible to grasp overall changes intuitively. |

Video walkthroughs

| Walk-through videos are produced by using synthesized point cloud data. These videos can be utilized for presentations and publicity videos regarding dismantlement plans and real estate information. |

Unique 3D measurement service

Draws a two-dimensional diagram | The 3D CAD models based on point cloud data are converted into drawings. It is also possible to produce drawings directly from point cloud data in a simple manner. |

Handles BIM/CIM modeling | Modeling is conducted with 3D CAD based on point cloud data. It is possible to produce models of the parts that require construction or renovation as BIM (building information modeling) data. |

Perfect 3D | This is a large-scale 3D data measurement service combining automobile-based MMS (mobile mapping system), airborne laser measurement, water area measurement, etc. |

3D printing | After modeling with point cloud data, data are processed and deformed so that they can be shaped with a 3D printer. It can produce fine structures with a lamination pitch of 15 μm. |

1-4 ROE analysis

| FY 1/19 | FY 1/20 | FY 1/21 | FY 1/22 | FY 1/23 | FY 1/24 | FY 1/25 |

ROE (%) | 23.8 | 2.3 | 5.6 | 40.6 | -1.5 | 5.5 | 9.2 |

Net Income to Sales Ratio (%) | 12.62 | 1.75 | 3.87 | 23.32 | -1.18 | 2.46 | 3.76 |

Asset Turnover Ratio (Times) | 1.08 | 0.72 | 0.67 | 0.80 | 0.63 | 0.97 | 0.99 |

Leverage (Times) | 1.75 | 1.85 | 2.14 | 2.19 | 2.01 | 2.28 | 2.45 |

The ROE in the fiscal year ended January 2025 is higher than that in the previous fiscal year. The new medium-term management plan, “Action Plan for Decarbonization 2025” (see below), targets “an ROE of 13% or higher in fiscal year ending January 2026.”

2. Fiscal Year Ended January 2025 Earnings Results

2-1 Consolidated results

| FY 1/24 | Ratio to sales | FY 1/25 | Ratio to sales | YoY | Company forecast ratio |

Sales | 9,394 | 100.0% | 10,897 | 100.0% | +16.0% | -0.9% |

Gross profit | 1,519 | 16.2% | 1,890 | 17.3% | +24.4% | - |

SG&A expenses | 1,272 | 13.5% | 1,517 | 13.9% | +19.2% | - |

Operating income | 246 | 2.6% | 373 | 3.4% | +51.3% | -25.3% |

Ordinary income | 407 | 4.3% | 592 | 5.4% | +45.2% | -8.9% |

Net income | 231 | 2.5% | 409 | 3.8% | +77.3% | -14.6% |

*Unit: million yen. Net income is net income attributable to owners of the parent company. The company forecasts are the forecasts announced in September 2024.

Sales and profit increased significantly

Sales grew 16.0% year on year to 10,897 million yen. The backlog of orders, including those for long-term large-scale projects received in the previous fiscal year, was ample, and the order receipt environment was favorable. In addition, the recruitment of personnel, which had been a bottleneck, was favorable, so their organizational structure was fortified, and plant demolition projects progressed smoothly. As a result, sales hit a record high.

Operating income rose 51.3% year on year to 373 million yen. The profits of consolidated subsidiaries were sluggish. However, Besterra’s plant dismantlement business, which is the mainstay, recorded a record-high profit of 577 million yen, as the company made efforts to shorten demolition periods by exercising their ingenuity in designing demolition methods and process management. Ordinary income increased 45.2% year on year to 592 million yen, and net income increased 77.3% year on year to 409 million yen. Sales and profit grew considerably, but they fell below the forecasts disclosed in September.

The company paid a year-end dividend of 10 yen/share as forecast for a total of 20 yen/share per year.

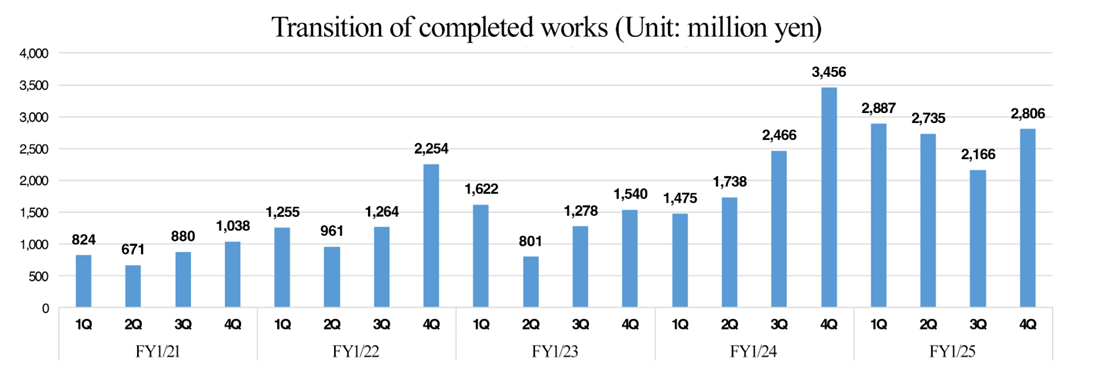

The number of completed works (rough estimates)

| FY 1/24 | Composition ratio | FY 1/25 | Composition ratio | YoY |

Electric power | 1,736 | 19% | 2,967 | 28% | +71% |

Steelmaking | 2,649 | 29% | 2,437 | 23% | -8% |

Petroleum/ petrochemical | 2,741 | 30% | 3,708 | 35% | +35% |

Gas | 274 | 3% | 212 | 2% | -23% |

3D | 91 | 1% | 106 | 1% | +16% |

Environment | 1,005 | 11% | 424 | 4% | -58% |

Others | 640 | 7% | 742 | 7% | +16% |

Total of completed works | 9,136 | 100% | 10,595 | 100% | +16% |

*Unit: million yen. Prepared by Investment Bridge Co., Ltd. based on company data.

In the fields of electric power, petroleum, and petrochemical, the company receives orders for large-scale projects and implements them as a primary contractor, so the composition of revenue from completed works are well-balanced.

The annual amount of completed works increased 16% year on year. Due to seasonal factors, the amount of completed works tends to increase around the end of each year and the end of each fiscal year, but in fiscal year ended January 2025, sales were stable throughout the year, thanks to long-term large-scale projects.

Breakdown of SG&A

| FY 1/24 | Ratio | FY 1/25 | Ratio | YoY | Major change factors |

Personnel expenses | 632 | 6.7% | 733 | 6.7% | +16.1% | Increase of employees |

R&D expenses | 14 | 0.1% | 59 | 0.5% | +317.9% | AI Development Project, Robot Development, Software development |

Fees and compensation paid | 149 | 1.6% | 167 | 1.5% | +12.1% | System costs, marketing cooperation expenses |

Recruiting expenses | 63 | 0.7% | 55 | 0.5% | -12.2% | Advertising media, introduction commissions |

Others | 413 | 4.4% | 500 | 4.6% | +20.9% | Amortization of goodwill, etc. |

Total SG&A expenses | 1,272 | 13.5% | 1,517 | 13.9% | +19.2% | An increase due to making Oda Corporation a subsidiary Approx. 116 million yen |

*Unit: million yen. Ratio is ratio to sales.

SG&A expenses, including goodwill amortization, augmented as Oda Corporation became a subsidiary of Besterra. In addition, spending on R&D for AI development, robot development, etc., and system costs to improve operational efficiency are increasing.

Through active recruitment activities, the number of dismantlement supervisors increased by 14 from the beginning of the fiscal year, hitting a record high, although it did not reach the target number 80. In fiscal year ending January 2026, the company plans to increase the number of dismantlement supervisors by 15. By April, the number of dismantlement supervisors is expected to increase by 7.

2-2 Orders received and the backlog of orders

| FY 1/24 | FY 1/25 | YoY |

The backlog of orders at the beginning of the term | 3,352 | 7,087 | +111.4% |

The amount of works received | 12,871 | 10,705 | -16.8% |

The amount of completed works | 9,136 | 10,595 | +16.0% |

The backlog of orders at the end of the term | 7,087 | 7,197 | +1.6% |

*Unit: million yen

The amount of works received decreased from the previous fiscal year, in which the company received orders for long-term large-scale projects, but the amount of completed works hit a record high and the company secured ample order backlog.

Orders received by sector (Amounts are approximate.)

| FY 1/24 | Ratio | FY 1/25 | Ratio | YoY |

Electric power | 1,205 | 17% | 1,223 | 17% | +2% |

Steelmaking | 3,614 | 51% | 3,670 | 51% | +2% |

Petroleum/ petrochemical | 1,913 | 27% | 1,871 | 26% | -2% |

Gas | 71 | 1% | 72 | 1% | +2% |

Environment | 71 | 1% | 144 | 2% | +103% |

Other | 213 | 3% | 216 | 3% | +2% |

Total order received | 7,087 | 100% | 7,197 | 100% | +2% |

*Unit: million yen

As the order receipt environment is favorable, the company maintained sufficient order backlog, by stably receiving orders in the fields of steelmaking, petroleum, petrochemical, and electric power, while recording the largest amount of completed works in their history.

2-3 Financial condition and cash flow(CF)

Financial condition

| January 2024 | January 2025 |

| January 2024 | January 2025 |

Cash | 1,444 | 1,599 | Payables | 1,631 | 1,186 |

Trade receivables | 4,648 | 5,137 | Borrowings and Bonds | 4,292 | 3,752 |

Current Assets | 6,292 | 7,130 | Liabilities | 6,783 | 6,192 |

Investments, Others | 3,960 | 3,473 | Net Assets | 4,095 | 4,853 |

Noncurrent Assets | 4,586 | 3,916 | Total Liabilities, Net Assets | 10,879 | 11,046 |

*Unit: million yen. Trade receivables include notes and accounts receivable, accounts receivable from completed construction contracts, and contract assets.

Total assets increased 160 million yen from the end of the previous fiscal year to 11 billion yen, mainly due to an increase in cash and

deposits through the sale of investment securities.

Total liabilities decreased 590 million yen from the end of the previous fiscal year to 6.1 billion yen, through the repayment of long-term debt, etc.

Net assets increased by 750 million yen to 4.8 billion yen due to the revaluation of investment securities and accumulation of net income.

Capital-to-asset ratio rose 6.3 points from the end of the previous fiscal year to 43.9%.

Cash Flow(CF)

| FY 1/24 | FY 1/25 | YoY |

Operating Cash Flow (A) | -1,422 | -607 | +814 |

Investing Cash Flow (B) | 24 | 1,482 | +1,457 |

Free Cash Flows (A + B) | -1,397 | 874 | +2,272 |

Financing Cash Flow | 1,503 | -719 | -2,223 |

Cash and Equivalents at Term End | 1,444 | 1,599 | +155 |

*Unit: million yen

Free cash flow turned positive, as the company posted revenue from the sale of investment securities, etc. The cash position improved.

2-4 Topics

① Business alliance for recycling waste

The company concluded a business alliance with J&T Recycling Corporation, which puts energy into the recycling of materials as resources, with the aim of reducing environmental burdens generated through the disposal and combustion of mixed waste (including waste plastics, lumber, glass, oil, and liquid) left after plant demolition.

Besterra | J&T Recycling (JFE Group) |

| Besterra has bases throughout Japan, so it can demolish plants in a broad range of area.After plant demolition, a lot of mono-materials are discarded.It can dismantle a variety of equipment for blast furnaces, power plants, petrochemical plants, etc. | J&T Recycling has bases throughout Japan, so it can dispose of waste in a broad range of area.By securing discarded mono-materials, it can recycle them as resources.They can foster constructive mutually-beneficial relationships.It offers comprehensive solutions, including environmental consulting, collection, transportation, intermediate processing, and recycling. |

Through this alliance, the company will share managerial issues, while considering the development of routes for recycling waste and metal scraps left after plant demolition, and cement the relationship between the two companies.

Initiatives for recycling resources for decarbonization

Many of materials discarded as waste have new value that is still to be discovered. The company considers that the recycling of such materials would take important roles for conserving the environment, managing resources, and establishing a sustainable society. The company makes efforts to recycle waste, while reducing the costs for disposing of waste left after demolition and utilizing resources effectively.

Recycling of windmill blades | Recycling of fire-proof bricks |

Dismantled blades are pulverized while removing glass fibers, and 100% recycled as cement. | Collected waste fire-proof bricks are sorted by a grizzly-type sieving machine or manually and recycled. |

|

|

(Source: The company)

Initiatives for decarbonized demolition

■ Biofuel

At the demolition sites of Besterra, the biofuel “SUSTEO” of Euglena is used. It is expected to reduce CO2 emissions during demolition work.

■ Hydrogen gas-based cutting

Mainly water vapor is emitted from hydrogen gas-based cutting. Through hydrogen gas-based cutting, it is possible to reduce CO2 emissions at demolition sites compared with normal gas cutting.

■ Bags for disposing of asbestos

In order to collect asbestos left at demolition sites, they use bags produced by recycling waste plastics 100% made in Japan. In addition, they have recently distributed brochures with QR-code stickers. When a user reads the QR code, the user can browse the reference material and formulas for confirming the reduction of CO2 emissions and the effects of the bags.

■ Curing sheets

A large number of curing sheets are used during environmentally-friendly demolition work (See the following figure).

(Source: The company)

The company is developing a product made of recycled plastics 100% made in Japan, like the bag for disposing of asbestos. With this, The company aims to reduce environmental burdens and realize sustainable demolition work.

② Adoption of the restricted stock-based remuneration (RS) system

The company will adopt a remuneration system for providing executives with shares whose transfer will be restricted until resignation or retirement (the restricted stock-based remuneration system).

● Provision of incentives: To contribute to the medium/long-term growth of the company by providing executives with treasury shares as incentives for improving business performance in the medium/long term

● Securing and retention of excellent personnel: To attract excellent personnel and retain them for a long period of time

● Unification of the viewpoints of shareholders and executives: When executives own treasury shares, the company aims to improve corporate value from the same viewpoint as shareholders, so the governance function is expected to improve.

■ The HR system for employees was revised in February 2025 (while revising the regulations for retirement benefits).

■ This system is aimed at realizing the growth of both employees and the company. Executives can receive benefits when contributing to the company or providing value.

■the company plans to adopt a bonus system linked with operating income.

The company will adopt remunerations for rewarding executives for improving corporate value and share price. On the other hand, the company will abolish the conventional system for providing executives with retirement benefits in cash regardless of corporate value (share price).

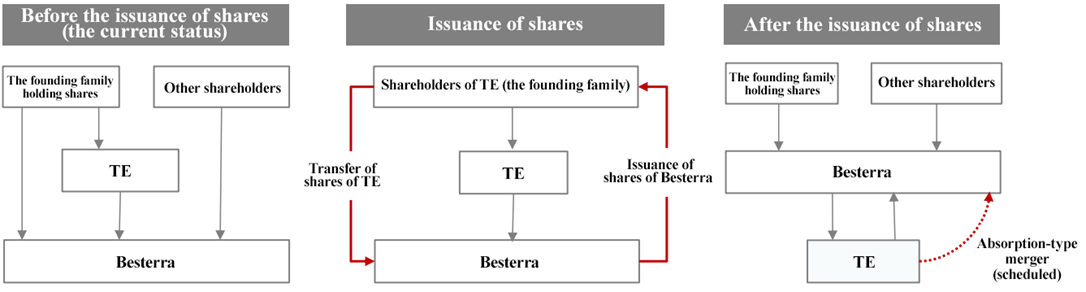

③ To make TERRA-ESHINO a subsidiary by issuing shares

The company will issue shares to reorganize TERRA-ESHINO (hereinafter referred to as “TE”), which manages assets of the founding family, into a subsidiary, for the purposes of improving the transparency of the composition of shareholders and the liquidity of shares.

● To improve the transparency of the shareholder composition and business administration by clarifying real shareholders

● To improve the liquidity of shares of Besterra by reorganizing the entrenched company for managing the assets of the founding family

● To issue shares so that Besterra will become the parent company and TE will become a subsidiary

● Since Besterra plans to absorb TE, the shares issued will become treasury shares, so shares will not be diluted. The company plans to retire the resultant treasury shares.

(Source: The company)

Unit: share | Before the issuance of shares | After the issuance of shares | After merger and retirement of treasury shares (planned) |

Number of outstanding shares | 8,990,200 | 10,227,200* | 8,787,200* |

Number of treasury shares | 129,035 | 129,035 | 129,035 |

Held shares of the subsidiary (mutually held shares) | - | 1,440,000 | - |

* It is assumed that all shareholders of TE will offer to sell shares, so the actual situation may be different.

3. Fiscal Year Ending January 2026 Earnings Forecasts

Full-year consolidated earnings forecast

| FY 1/25 Act. | Ratio to sales | FY 1/26 Est. | Ratio to sales | YoY |

Sales | 10,897 | 100.0% | 13,000 | 100.0% | +19.3% |

Operating income | 373 | 3.4% | 1,200 | 9.2% | +221.2% |

Ordinary income | 592 | 5.4% | 1,280 | 9.8% | +116.2% |

Net income | 409 | 3.8% | 900 | 6.9% | +119.6% |

*Unit: million yen

Forecast double-digit growth of sales, and significant growth of profit.

For the fiscal year ending January 2026, sales are expected to grow 19.3% year on year to 13 billion yen and operating income is projected to rise 221.2% year on year to 1.2 billion yen.

The company will actively make efforts to receive orders for large-scale projects, which are expected to produce profit stably, manage costs thoroughly, and secure personnel. In addition, order backlog is at a high level, and the company will make continuous efforts to receive orders for plant demolition. The company upwardly revised the target sales set in “Action Plan for Decarbonization 2025” from 12 billion yen to 13 billion yen. In terms of profit, the company will try to stabilize profit by increasing sales, actively recruit construction personnel, and improve the precision in price estimation and cost management by utilizing IT technologies, including AI. While selecting and concentrating on specific businesses, The company will consider the integration, discontinuation, or sale of some businesses.

Regarding dividends, the company plans to pay a total of 30 yen/share (including an interim dividend of 15 yen/share) per year, up 10 yen/share from the previous fiscal year. The expected payout ratio is 29.5%.

4. The medium-term management plan “Action Plan for Decarbonization 2025”

In the fiscal year ended January 2023, both sales and profit were significantly below initial forecasts. Thus, the company has formulated a new medium-term management plan, Action Plan for Decarbonization 2025, in place of the Medium-Term Management Plan 2025, which it has been implementing since the fiscal year ended January 2022. Under the new management system, the company will position the fiscal year ended January 2024 to the fiscal year ending January 2026 as a turning point for further growth. The company decided to improve profitability by promoting decarbonization-oriented management and reforming its corporate culture, taking into account changes in the business environment in Japan and within this industry.

4-1 Business environment analysis

(1) Japan

Toward the realization of carbon neutrality in 2050, the demolition market is expected to expand further, with demolition progressing mainly for buildings in which 50 years or more have passed since their construction.

In the electric power market, the diversification of the energy mix will be significantly reviewed toward 2030, and a significant reduction of low-efficiency coal-fired power plants is expected.

In the steel manufacturing market, due to the progress of corporate restructuring and aging, it is necessary to remove and repair redundant facilities.

In the petroleum and petrochemical markets, many industrial complexes were built during the high economic growth period. Therefore, it is expected that facilities will be upgraded and reorganized from the perspective of international competitiveness and excessive production capacity.

In other manufacturing markets, facilities are expected to be renovated and dismantled due to the evolution of technology known as the 4th industrial revolution and the impact of business rationalization due to changes in domestic supply and demand.

The company estimates the size of each market as follows.

Market | Size |

Electric power | About 13 trillion yen |

Steel | About 2 trillion yen |

Petroleum/Petrochemicals | About 8 trillion yen |

Other manufacturing industries | About 20 trillion yen + α |

*Company’s estimates

(2) Industry

The following changes in the business environment and needs can be seen.

Increase of separate orders for dismantling | When a client (facility owner) places an order with a company specializing in demolition, there are many cases in which the reliability of the demolition company as a new business partner becomes a problem, as it is necessary to place an order with a company that complies with all laws and regulations and meets the high safety standards of each plant. In order to receive direct orders, the demolition company needs to be a listed company with high creditworthiness and possesses technologies that do guarantee not only safe demolition but are also safe for the environment. In conventional plant demolition work, there were many cases in which a client (facility owner) ordered the demolition of old facilities and the construction of new ones together. Due to the increase in demolition work that does not involve renewal and the rising difficulty of demolition work due to various laws and regulations, the orders for demolition work to specialized construction companies are increasing. |

Adopting computer-aided construction | Due to the labor shortage in the construction industry because of the declining birthrate and aging population, efforts to computerize construction have become an issue for the industry. |

New needs for decarbonized work | Clients (facility owners) in the manufacturing industry are demanding environmental considerations and improved recycling rates not only in the manufacturing process but also in construction. |

(3) Company’s strengths

The company has a superior position as a plant demolition specialist (a rich track record), technological capabilities (decarbonized demolition®, patented methods, technology development, initiatives for DX), business alliances (Solution-offering capabilities for the entire venous industry), reliability, comprehensive plant demolition management (demolition method proposals, complying with environment-related laws and regulations, ability to purchase valuable materials, appropriate treatment of industrial waste, ability to mobilize companies, etc.). In response to the above needs and changes, it will harness these strengths to capture demand.

4-2 Overview of Action Plan for Decarbonization 2025

(1) Basic policy

The company's basic policy is to improve profitability through decarbonization-oriented management and transformation of the corporate culture.

Seeing changes in the business environment as an opportunity, the company will promote decarbonization-oriented management and reform its corporate culture to improve profitability, and it has positioned the three years from the fiscal year ended January 2024 to the fiscal year ending January 2026 as a turning point toward further growth.

(2) Numerical targets

① The sales in fiscal year ended January 2025 reached the initial forecast for fiscal year ending January 2026 (10 billion yen) as plant dismantlement business progressed smoothly, thanks to the favorable order receipt environment and the strengthening of their organizational structure through healthy recruitment of personnel.

② The insufficient performance of the DX business is covered by the plant dismantlement business, which is the core business. Group companies, including the DX section, will select and concentrate on specific businesses, and integrate, discontinue, or sell some businesses.

③ The forecast profit for fiscal year ending January 2026 was left unchanged, while considering the receipt of orders from new clients as a primary contractor and the increase of competitors.

④ Equity spread is 4% or over, and the company aims to increase it further.

(Source: The company)

(3) Trend in each field

3-1 Electric power field

In the 7th basic energy plan announced by the Agency for Natural Resources and Energy, the company aims to increase the ratio of renewable energy to 40-50% and keep the ratio of thermal power generation 30-40%.

From the viewpoints of stable supply of energy and decarbonization, the company will adopt renewable energy, which has a significant decarbonization effect as a core power source, as much as possible, and reduce the output of thermal power generation, mainly inefficient coal-fired one.

Major plans to dismantle thermal power plants

J-POWER | Matsushima Thermal Power Plant was dismantled at the end of FY 2024. Takasago Thermal Power Plant is to be dismantled in FY 2028. Takehara and Matsuura Thermal Power Plants are to be temporarily stopped or dismantled or used as a standby power system. |

JERA | Kashima Thermal Power Plant No. 1-6 were dismantled in March 2023. All of coal-based thermal power plants, which are inefficient, are scheduled to be stopped or dismantled by 2030. |

Chugoku Electric Power | Kudamatsu Power Plant No. 2 was dismantled in January 2023. Mizushima Power Plant was dismantled in April 2023. Shimonoseki Power Plant No. 1-2 were dismantled in January 2024. |

In addition, several companies, including Tohoku Electric Power, Kyushu Electric Power, and Shikoku Electric Power, plan to dismantle their thermal power plants.

3-2 Ironmaking field

Equipment is being upgraded to cope with the changes in domestic demand and take environmental measures.

The demand for iron and steel in Japan is declining, due to the economic downturn, the shrinkage of the population, the growth of overseas ironmaking industries, etc. In addition, it is imperative to upgrade equipment, as the shift from blast furnaces to electric furnaces and research into hydrogen-reduction ironmaking are progressing for decarbonization.

Decarbonization in production of iron and steel

Shift to electric furnaces | Nippon Steel: Switch from blast furnaces to electric furnaces in the Yahata District; construction of new electric furnaces in the Hirohata District JFE Steel: Replaced a blast furnace with a large-sized electric furnace in the Kurashiki District |

Hydrogen-reduction ironmaking | Nippon Steel: A 43% reduction in CO2 emissions was observed in a test conducted from November to December 2024 |

Growth of demand for highly functional steel materials

The demand for fuel-efficient automobiles and highly efficient power generation equipment for achieving carbon neutrality is growing, so each company puts energy into the production of highly functional steel materials. Accordingly, the replacement and upgrade of production equipment can be expected.

3-3 Fields of petroleum and petrochemical

As petrochemical complexes have deteriorated and ethylene equipment decreased due to the change in domestic demand, the integration and disposal of equipment have been progressing.

Most complexes were constructed in the high economic growth period, so the company has been operated for over 50 years. For the replacement, integration, and dismantlement of equipment, the demand for plant demolition is growing.

(Taken from the reference material of the company)

Integration and dismantlement of ethylene plants

Several companies are discussing the replacement of ethylene plants in complexes, as demand and utilization rate have declined. In Chiba, Maruzen Petrochemical, Sumitomo Chemical, Idemitsu Kosan, and Mitsui Chemicals expressed their intention to integrate equipment. In the Mizushima area, Asahi Kasei and Mitsubishi Chemical plan to optimize the production structure.

Decline in demand for plastics and decrease of production equipment

Plastics account for 60% of petrochemical products. Recently, the demand for plastics has shrunk and production amount has been decreasing, as companies have taken environment-conscious measures. Accordingly, plant equipment is projected to decrease.

3-4 Other manufacturing fields

Due to digitalization and growth of demand related to electric vehicles, capital investment has increased and restructuring has become active.

While the rise in interest in utilization of AI and digitalization is increasing demand, the demand in the papermaking and other manufacturing fields is shrinking.

Automobile industry

The Ministry of Economy, Trade and Industry upholds the goal of increasing the ratio of electric vehicles to new cars sold to 100% by 2035, so an increasing number of hybrid cars and EVs are distributed. On the other hand, the production number of automobiles is declining.

Papermaking industry

As the domestic demand for paper and paperboard is shrinking, several companies are replacing or dismantling production equipment. Nippon Paper Industries will stop some production equipment by the end of 2025. Oji Holdings plans to close Fujinomiya Factory in January 2026.

Semiconductors

As enterprises put energy into the utilization of AI and digitalization, the investments in the upgrade and enhancement of capacity of semiconductor manufacturing equipment are increasing, and the production output of semiconductor manufacturing equipment is growing.

(4) Records of major strategies in FY 1/25

Priority strategies

Primary measures | Details |

Enhancement of marketing activities | ・ Increase of business partners and receipt of orders as a primary contractor ・ Improvement in precision of price estimation with AI tools ・ Establishment of the engineering division that specializes in the estimation of costs and prices ・ Sophistication of methods for collecting, sharing, and using information with a marketing support system |

Promotion of DX | ・ Improvement of functions and diversification of specs of robots for inspecting crane rails ・ Release of AUTOCAD Plant 3D Add-on tool “ASTO” ・ Certified as a service provider of Autodesk Inc. |

Expansion of business scale | ・ Formation of a business alliance for realizing a resources recycling society with J&T Recycling Corporation ・ Foray into the overseas market of plant demolition ・ Conclusion of a strategic partnership contract with DENZAI K.K. |

Promotion of environment-conscious management | ・ Promotion of on-site decarbonization measures (hydrogen gas-based cutting and use of biofuel) ・ Promotion of measures for recycling (windmill blades, fire-proof bricks, etc.) ・ Proposal for development of materials for demolition work using waste plastics and promotion of sales of them ・ Got the score “B-” in “Climate Change Report 2024” of CDP. |

Tightening of corporate governance | ・ Stepwise reduction of strategically held shares (In FY 1/25, they sold 30% of initially held shares.) |

Revision to the policy for shareholder return | ・ Adoption of progressive dividends (aiming to achieve a payout ratio of 40% and a DOE of 3.5% or higher) |

HR strategies

Primary measures | Details |

Enhancement of recruitment, and diversity management | ・ The largest number of dismantlement supervisors employed in their history (up 14, reaching 20) ・ Promotion of female employees to demolition managers ・ Promotion of employment of disabled people (they hired two disabled people) |

Establishment of educational programs | ・ Establishment of a program for educating prospective employees ・ Improvement in the training of new employees (addition of the training in the demolition work division) ・ Establishment of an OJT system and an OJT program with a skill check sheet ・ Holding of a monthly management workshop and training of managers |

Knowledge management | ・ Adoption of a HR system aimed at managing personnel data in a unified manner and utilizing them ・ Adoption of a group-wide database system aimed at managing group-wide information and knowledge in a unified manner, utilizing them, and streamlining business operations |

MVP commendation system | ・ Commended the MVP at a general conference of employees ・ Adopted a commendation system for conveying gratitude on a daily basis (commending employees a total of 150 times) |

Environment where employees can work without worry for a long period of time | ・ Revised the welfare systems for improving the engagement of employees ・ The treatment of employees rehired after the retirement age was kept unchanged from the treatment before the retirement age. ・ The ratio of male employees who took childcare leave was 100%. |

Revision to the evaluation and remuneration systems | ・ Formulation of guidelines for behavior for all employees (pride, co-creation, and endeavor) ・ Development of a new HR system aimed at realizing the growth of both employees and the company |

Age composition that enables sustainable growth

Employees in their 20s and 30s account for over 50% of employees of Besterra. In the construction industry, employees in their 50s and 60s account for over 50% on average. Meanwhile, the composition of employees of Besterra allows sustainable business growth. The company will keep recruiting dismantlement supervisors actively and diversify employees by recruiting more women and non-Japanese people.

The company will also enrich the system for reemployment after the retirement age.

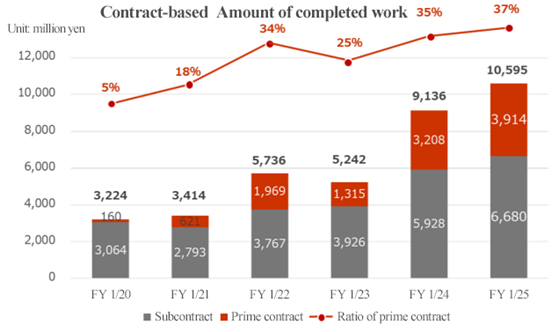

◎ To receive more orders for decarbonized demolition® projects as a primary contractor

As the demand for demolition grew and the company concentrated on marketing activities, the ratio of projects the company has undertaken as a primary contractor is increasing. The demolition projects the company has undertaken as a primary contractor facilitate the development of personnel and the streamlining of demolition works. In the case of new clients, profit margin is sometimes low due to marketing measures, but the company aims to receive orders for future growth.

(Source: The company)

Advantages of projects the company undertakes as a primary contractor

Advantages 1 Development of personnel for business growth | Projects they undertake as a primary contractor include a variety of tasks, so they can be involved with actual tasks at an early stage. In such projects, they manage all processes, so they can learn the entire picture of on-site processes, and are expected to acquire advanced knowledge through the cooperation with clients and train the skills of dismantlement supervisors. In addition, the required number of supervisors is large, so even inexperienced employees are helpful and indispensable at each site. |

Advantages 2 Unique demolition methods can be used | The company has invented a lot of unique demolition methods, and concentrates on the acquisition of patents. In such projects, they have considerable discretion and a high degree of freedom, so they can proceed with the projects safely and efficiently by selecting optimal methods and incorporating them into processes. |

Advantages 3 Improvement in profit margin through the direct receipt of orders | In such projects, they receive orders directly from clients, so profit margin is expected to improve. In addition, if demolition periods can be shortened with their unique methods and safety standards, new opportunities will emerge. |

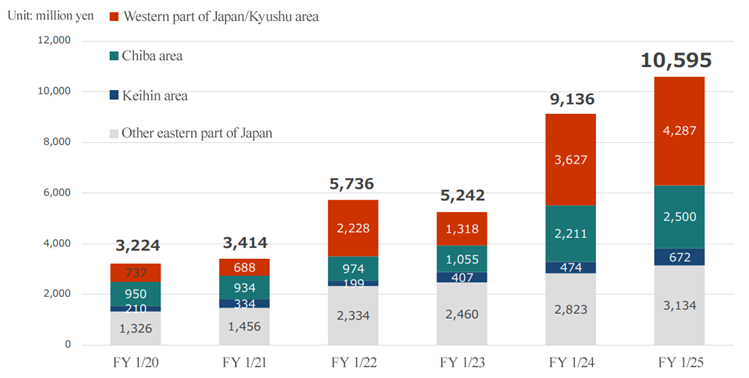

◎ Amount of completed works in each region

In order to meet plenty of demand for demolition in western part of Japan and Kyushu area, the company enriched bases, including Kurashiki Office and Kyushu Office, and concentrated on the receipt of orders for recurring projects there. As a result, sales grew considerably, and the company receives orders continuously.

Region-specific Amount of completed work

(Source: The company)

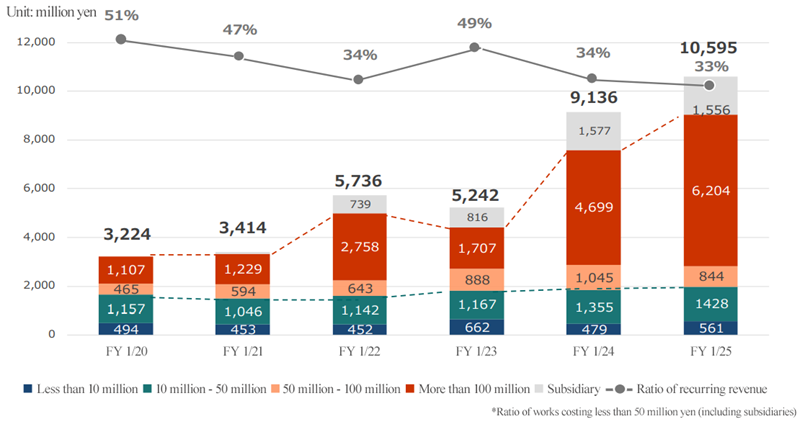

◎ Amount of completed works for each scale

By receiving orders for recurring projects (continuous projects at the same sites), the company has established a community-based marketing system. As a result, the number of orders for medium/large-scale demolition projects with a revenue of 100 million yen or over has been increasing significantly.

Scale-specific Amount of completed work

(Source: The company)

(5) Shareholder Returns

The company will pay stable dividends with a target payout ratio of 40% and a DOE of 3.5% or higher.

In the fiscal year ended January 2023, the company changed (expanded) its shareholder benefits and established the "Besterra Premium Benefits Club."

For details of the "Besterra Premium Benefits Club," please refer to the following URL:

https://besterra.premium-yutaiclub.jp/

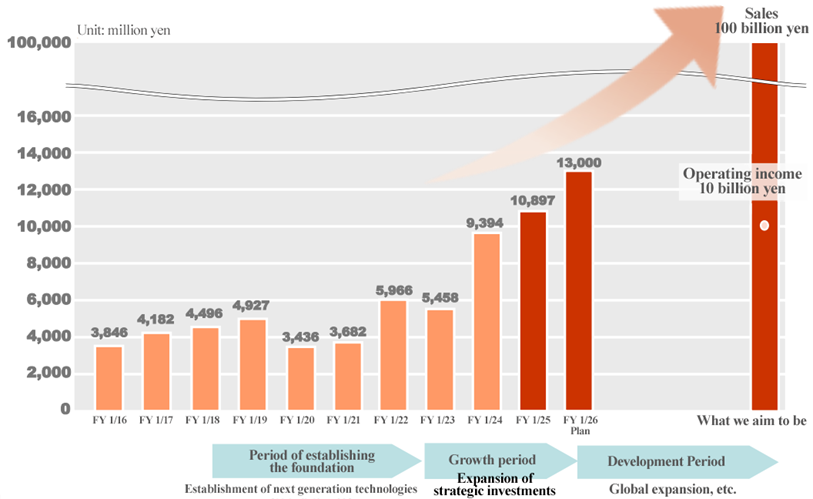

(6) Long-term vision: Objectives of BESTERRA

Aim to achieve sales of 100 billion yen and operating income of 10 billion yen as soon as possible.

(Source: The company)

5. Conclusions

In the fiscal year ended January 2025, it seems that Besterra faced a significant turning point. While sales have been growing, the company strove to earn profit through trial and error while having some unprofitable projects, as an operating loss was posted in the fiscal year ended January 2023. In the fiscal year ended January 2025, group companies struggled, so profit seems to be low, but the performance of the plant dismantlement business improved significantly and operating income hit a record high. In the fiscal year ending January 2026, the company will try to shore up group companies while continuing efforts to improve sales and profit margin of the plant dismantlement business. Accordingly, it is expected that profit margin will improve while sales will keep grow considerably and profit will increase significantly.

Regarding the seemingly audacious goal of achieving “sales of 100 billion yen and an operating income of 10 billion yen,” President Honda commented, “It seems to be more feasible.” This comment makes him more dependable. Although it was challenging to secure sufficient manpower, the company has recruited the largest number of dismantlement supervisors in their history, to overcome the issue. It seems that the development of an organizational structure for dealing with significant sales growth is progressing as the company is recruiting personnel steadily. Since assuming the post of president in 2023, President Honda has conducted various investments, and it is time to see their outcomes.

Sales are growing significantly and profit margin is improving, but the reflection of them in share price is delayed. If improvements become evident, share price will probably increase accordingly. We would like to pay attention to the quarterly progress.

<Reference: Regarding Corporate Governance>

◎ Organization type and the composition of directors and auditors

Organization type | Company with an audit and supervisory committee |

Directors | 8 directors, including 5 outside ones |

Auditors | 3 auditors, including 3 outside ones |

◎ Corporate Governance Report Update date: April 25, 2024

Basic policy In order to promote sound business administration and win social trust sufficiently, our company recognizes corporate governance as the most important issue, puts importance on the improvement of the soundness, transparency, and fairness of business administration, and complies with laws and regulations thoroughly, and all executives operate business while keeping in mind that “the violation of laws or regulations would lead to management responsibility.” In detail, our company disseminates and executes business pursuant to laws, regulations, and in-company rules thoroughly, by developing appropriate systems for making decisions about business administration, fulfilling duties, supervising work, conducting internal control, etc. It is also important to reform management systems for “achieving appropriate share price” and “increasing share price sustainably” to emphasize shareholders and strengthen the function to check business administration, to establish global-level corporate governance. The results of such efforts would win the trust of society, increase corporate value, and satisfy shareholders.

<Reasons for Non-compliance with the Principles of the Corporate Governance Code (Excerpts)>

[Supplementary Principle 4-1-3]

We do not have a concrete plan regarding the successor of the CEO. As for the Board of Directors, the policy regarding the selection of successors is to take into consideration the personality, insight and accomplishments of each candidate and select a suitable person. In case of formulating and conducting a plan regarding the successor, we shall ensure the fairness, transparency and objectivity of the decision process and appropriately proceed with the selection by involving the Nomination and Compensation Committee, an advisory institution to the Board of Directors where outside directors account for the majority, alongside proactive involvement of the Board of Directors.

[Supplementary Principle 4-3-3]

While we have not clearly established objective, timely and transparent proceedings for the dismissal of the President or CEO, we assess the effectiveness of the Board of Directors every year and shall progress with objective, timely and transparent proceedings through the involvement of the Nomination and Compensation Committee, where outside directors account for the majority, in regard to the nomination and compensation of directors.

<Disclosure Based on the Principles of the Corporate Governance Code (Excerpts)>

[Principle 1-4 Strategically held shares]From the viewpoint of business expansion based on maintaining and strengthening long-term, stable partnerships with business partners, etc., we will acquire and hold the shares of business partners, etc., if we judge that this will contribute to the improvement of our mid/long-term corporate value. For equity investments premised on forming business alliances, the management meets with and receives explanations of the operating environment, business strategy, and purposes of the capital alliance from representatives of the other party. Based on this, the Board of Directors comprehensively evaluates the appropriateness of the stock valuation report and judges whether the deal should take place. For strategically held shares, the Board of Directors constantly checks whether the holding of such shares will contribute to the improvement of our corporate value and confirms the purpose and rationality of said holding based on that check. Our company will appropriately buy/sell shares and exercise voting rights in accordance with relevant regulations, based on a comprehensive evaluation from the viewpoint of improving our corporate value.

[Supplementary Principle 3-1-3 Measures for sustainability]

Our company discloses initiatives concerning sustainability in the mid-term management plan and on our website. Moreover, in order to clarify initiatives for sustainability, we shall set up a Sustainability Committee as an advisory institution of the Board of Directors to control and manage the initiatives in addition to establishing the basic sustainability policy. Furthermore, we view the recruitment and education of human resources as an important challenge for improving our corporate value in the mid- to long-term and we shall create a system which will allow for independent building of career and build a free and lively corporate culture based on diversity to seek the reinforcement of human capital.

As for risks and opportunities for gaining income related to climate changes, we shall respond to the proposal by TCFD in expressing the endorsement of TCFD and participating in TCFD Consortium, and we shall proactively engage in enriching the quality and quantity of disclosures based on TCFD and equivalent frameworks and forge ahead with the enrichment of disclosure on our company website, etc.

[Principle 5-1 Policy on constructive dialogue with shareholders]Regarding requests from shareholders for dialogue (interviews), our company believes that we should express a positive attitude within a reasonable scope in order to contribute to sustainable growth and medium- and long-term improvement of the corporate value of our company. Aiming to promote constructive dialogue with shareholders, with the planning department designated as a department in charge of IR activities, our company holds financial results briefings targeted at financial institutions and investors semiannually and discloses corporate information as needed on our website and through the system of optional disclosure offered by Tokyo Stock Exchange.

[Actions to Achieve Management Conscious of Cost of Capital and Stock Price]

Our company has formulated the "Decarbonization Action Plan 2025," which clearly defines its contribution to a more decarbonized society and defined key strategies and implemented various measures to improve its corporate value over the medium/long term. Our company estimates its current cost of equity to be around 6%. Regarding the balance between cost of capital and return on capital, the average ROE over the past nine years has been 13.2%, and our company considers the equity spread under normal circumstances to be around 7%.

However, regarding the decline in ROE over the past four years, our company recognizes that this is due to a temporary decline in the operating income margin of the plant dismantling business caused by one-time losses from projects that occurred during the management changeover and the acceptance of low-profit projects aimed at stabilizing profits through the expansion of sales scale, as well as the costs associated with actively hiring construction personnel, which is an important factor in scaling up.

In the fiscal year ending January 2026, the final year of the medium-term management plan "Decarbonization Action Plan 2025," our company expects that these temporary factors will disappear, and the scale of operations will exceed fixed costs, leading to an improvement in the earnings structure. As a result, our company anticipates that ROE will exceed 13% and equity spread will exceed the usual 7%.

Based on the current assessment, our company will steadily promote its business in order to achieve sales of 12 billion yen and an operating income of 1.2 billion yen in the fiscal year ending January 2026, the final year of the medium-term management plan "Decarbonization Action Plan 2025." By improving profitability through the expansion of its scale, it aims to achieve an ROE of 13% or higher and further enhance its PBR. At the same time, we will strengthen our efforts in appropriate growth strategies, financial strategies, and other initiatives. For more details, please refer to the disclosed documents regarding our company's measures to achieve management that is mindful of the cost of capital and share price.

This report is not intended for soliciting or promoting investment activities or offering any advice on investment or the like, but for providing information only. The information included in this report was taken from sources considered reliable by our company. Our company will not guarantee the accuracy, integrity, or appropriateness of information or opinions in this report. Our company will not assume any responsibility for expenses, damages or the like arising out of the use of this report or information obtained from this report. All kinds of rights related to this report belong to Investment Bridge Co., Ltd. The contents, etc. of this report may be revised without notice. Please make an investment decision on your own judgment. Copyright(C) Investment Bridge Co., Ltd. All Rights Reserved. |