| YAMABIKO CORPORATION (6250) |

|

||||||||

Company |

YAMABIKO CORPORATION |

||

Code No. |

6250 |

||

Exchange |

TSE 1st Section |

||

Industry |

Machinery (Manufacturing) |

||

President |

Yoshiaki Nagao |

||

Address |

1-7-2, Suehiro-cho, Ome-shi, Tokyo, Japan |

||

Year-end |

End of December |

||

URL |

|||

* The share price is the closing price on December 8. The number of shares issued and BPS were taken from the latest brief financial report.

ROE is the actual values for the previous term. * FY December 2017 lasts for only 9 months due to the change of accounting periods. |

||||||||||||||||||||||||

|

|

*The forecast is from the company. It undertook a 1:4 stock split as of October 1, 2015. EPS and DPS have been retrospectively adjusted.

*From the FY 3/16, net income is profit attributable to owners of the parent. Hereinafter the same shall apply. * FY December 2017 lasts for only 9 months due to the change of accounting periods. This report introduces YAMABIKO CORPORATION's Earnings Results of First Half of Fiscal Year December 2017 and so on. |

| Key Points |

|

| Company Overview |

|

KIORITZ CORPORATION was established in 1947 in Tokyo and originally called KIORITZ AGRICULTURAL EQUIPMENT CORPORATION. It has been a leading company in both agricultural equipment business through which they developed "Japan's first speed sprayers" and outdoor power equipment business through which they developed "Japan's first motorized backpack trimmers" and "the world's first handheld power blowers". Furthermore, since its establishment, it has been focusing on self-development of engines for outdoor power equipment. The accumulative number of engines produced in 2008, before the merger, was about 40 million. Shindaiwa Corporation was established in 1952 in Hiroshima and was originally called Asamoto Precision Manufacturer. It developed "Japan's first electric chain saws" for the outdoor power equipment business, and manufactured and sold engine generators and engine welders for the industrial machinery business. Its strength was high technological development capabilities, as can be seen in the development of the world's first mixed fuel 4-cycle engine. In the late 1990s, with growing concern about global warming caused by greenhouse effect gas, and as engine's emission gas control became stricter in the West, especially in the US, research and development expenses increased to comply with the new regulations. In the 2000s, the medium and small-sized companies that could not afford these expenses went through rapid industry restructuring on a global scale in the outdoor power equipment industry. Moreover, the business environment became further uncertain due to a flood of cheaper products from newly emerging countries and diversification of customers' needs. Under these circumstances, the two companies concluded a business and capital alliance agreement in May 2007 on the premise of future business integration in order to strengthen the vitality to survive and win the intensifying competition. In December 2008, YAMABIKO CORPORATION was established as a joint holding company to achieve better efficiency and expansion for all its businesses including development, manufacturing, logistics, sales and management. In October 2009, YAMABIKO CORPORATION conducted an absorption-type merger of Kioritz and Shindaiwa and became the current business entity. The company name "YAMABIKO" derives from the mountain god, "Yamabiko". Its corporate philosophy is to "create the bridge that bonds people and nature with the future". This expresses the Company's willingness to contribute to the conservation and improvement of the nature and environment. "Essence", which incorporates both "Purpose of Existence" and "Code of Conduct", expresses in a single word what YAMABIKO Group aims to be as a company, and the essence of its corporate activities. "Purpose of Existence" sets out the role and responsibilities of YAMABIKO Group in society, and makes a commitment to this. "Code of Conduct" defines the attitude of each YAMABIKO Group employee in relation to their work.   President Nagao disseminates messages that are based on "Essence", "Purpose of Existence" and "Code of Conduct" at various occasions. They are also making daily efforts so that the corporate philosophy would lead to each employee's actual activities in each workplace. * Profile of President Yoshiaki Nagao

President Yoshiaki Nagao was born in February 1953 (Age 64). Since his childhood, he enjoyed "creation" such as building plastic models. When he was in the middle school, his interest grew in automobiles, especially those made in the US. He majored in "combustion engineering" in graduate school, where he studied engines. He began working at KIORITZ CORPORATION in April 1978. At KIORITZ, he worked at the research department. He was involved with research and development of various engines, especially chain saws engines, under the corporate culture that supported the employees' spirit to find and work on the issues of their interest. Instead of focusing on his research only in the lab, he went out to the mountains and interviewed woodsmen who were the users of their products to hear opinions and identify the demands in detail. After working in the technology area for most of his time at KIORITZ, he was appointed as President and CEO of ECHO Incorporated, an affiliate of KIORITZ in the US in February 2006. His focus at ECHO Incorporated was to observe the actual situation of the emission gas control regulations in the US, to find measures to meet the regulations, and to enhance the users' satisfaction. During the merger process of KIORITZ and Shindaiwa, he facilitated fast and drastic organization of the local sales routes. He recalled, "It was an important step to diversify my work". After the establishment of YAMABIKO CORPORATION, he managed to implement smooth integration as a board director / managing officer / industrial machinery division officer in Hiroshima where the head office of Shindaiwa Corporation was located. In June 2011, he was appointed CEO and President of YAMABIKO CORPORATION. The company recognizes that there are two global manufacturers of outdoor power equipment in Europe (Germany and Sweden). 1. Segment

YAMABIKO Group operates businesses in three sectors: Outdoor power equipment, Agricultural machinery and Industrial machinery.The reporting segments are "Outdoor power equipment", "Agricultural machinery", "Industrial machinery". These of sales and income data are disclosed. From FY December 2017, the company uses new business segments as follows.  "Outdoor power equipment business"

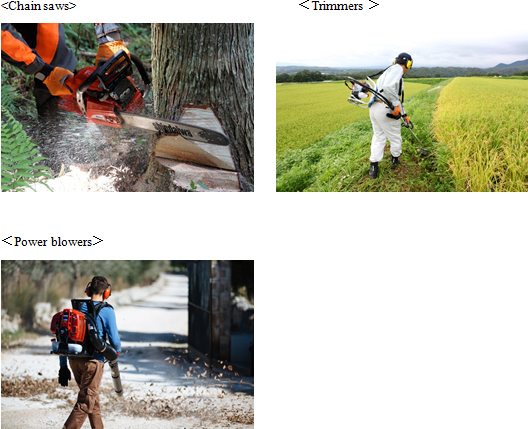

YAMABIKO CORPORATION manufactures and sells handheld or backpack-style forestry and landscape maintenance machinery powered by small internal combustion engines. The main products include chain saws, trimmers, power blowers, hedge trimmers, etc.In Nov. 2014, the company acquired "Belrobotics SA," a Belgian venture company, which develops, manufactures, and sells robotic mowers for professional use. (In Jan. 2017, Belrobotics SA was renamed "Yamabiko Europe SA" for the purpose of enhancing sales in Europe.) Based on the accumulated experiences and know-how and excellent development capabilities that meet the customers' needs, YAMABIKO CORPORATION continues to produce high performance, highly durable and high-quality engines.  (Gasoline engine system)

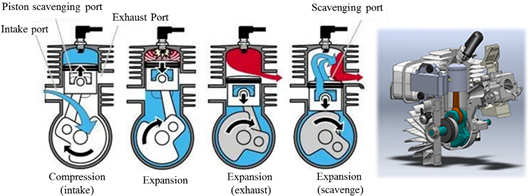

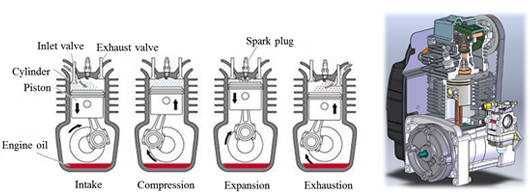

The engines for outdoor power equipment such as chain saws and trimmers are mainly 2-stroke gasoline engines. As described later, the Company's excellent capability to develop engines is one of their most important features/strengths. Brief information concerning the Company's engines is provided below because knowing the gasoline engine system and characteristics of each engine type helps to understand the business of the Company, Basically, a gasoline engine generates power by moving the piston down with the combustion of gasoline through the following 4 steps.  The gasoline engine is largely categorized in two types (2-stroke engine and 4-stroke engine), depending on the number of reciprocating motion by piston to complete "1 cycle" of the 4 steps. "2-stroke engine"

One power cycle is completed by 2-stroke. In other words, a power is generated by "1 piston reciprocating motion, 1 crankshaft revolution". First stroke (piston moving up): "Intake" and "compression" of air-fuel mixture occur. Second stroke (piston moving down): Piston moves down due to the "expansion" of air-fuel mixture and "exhaustion" occurs later.  "4-stroke engine"

One power cycle is completed by 4-stroke. A power is generated by "2 piston reciprocating motions, 2 crankshaft revolutions".First stroke (piston moving down): "Intake" of air-fuel mixture occurs. Second stroke (piston moving up): "Compression" of air-fuel mixture occurs. Third stroke (piston moving down): Piston rapidly moves down as a result of "expansion". Fourth stroke (piston moving up): Combusted gas is "exhausted".  On the other hand, a 2-stroke engine has a larger ratio of burning engine oil and fuel in order to make smooth piston motion and blow-by of air-fuel mixture. This means it releases more harmful substances in the exhaust gas as compared with a 4-stroke engine. However, because of its simple structure and smaller number of parts, the 2-stroke engine can be smaller and lighter. The overhaul is also easier for the same reasons. Therefore, a 2-stroke engine is the most appropriate engine for outdoor power equipment. "Agricultural machinery business"

YAMABIKO CORPORATION manufactures and sells pest control equipment for Japan and agricultural harvesting equipment for North America. Its major products include pest control equipment (speed sprayers, mounted equipment for cropland pest control, power sprayers), sloop mower, soy and potato harvesters, etc. YAMABIKO CORPORATION's technological strengths in this business segment are KIORITZ's blowing, spraying, and pumping technology as well as technology to create small and light equipment. These technological capabilities have been built up over many years at KIORITZ.  "Industrial machinery business"

YAMABIKO CORPORATION manufactures and sells equipment for construction, civil engineering and iron works. Its major products include generators, welders, lighting equipment, cutting machines and high-pressure washers. Technological strengths in this business segment are established by long years of R&D which began at the time when YAMABIKO CORPORATION started business as Shindaiwa, and such strengths can be found in alternator designing capability improved by their efforts for alternative current motor development, as well as technologies for electronic control and noise prevention.  "Others"

The Company manufactures and sells accessories and the parts for after purchasing service for various machines and equipment. As shown in the graph on Page 5, the profitability in this segment is the highest in all segments.  2. Brand

YAMABIKO CORPORATION was established based on the integration of two companies. The products of both companies are well recognized both in Japan and overseas for many years. Therefore, YAMABIKO CORPORATION maintains the brand names as KIORITZ, Shindaiwa, and ECHO. YAMABIKO CORPORATION is proactively investing in marketing as well as exploring new sales routes to enhance its brand values.  3. Development structure

Each business segment is working on development with a focus on the following priority issues.

In addition, the Company is conducting research on control technology in the field of electronic control. 4. Production structure

The Company has 3 plants (Yokosuka, Morioka, and Hiroshima) and 4 production related subsidiaries in Japan and a total of 8 production related subsidiaries in the USA, Belgium, China and Vietnam.

5. Sales route and sales methods

The Company supplies its products in over 90 countries for about 28,000 stores. More than 60% of the sales are from overseas sales.  <Domestic market>

7 sales subsidiaries were merged into YAMABIKO JAPAN CO., LTD in April 2017. YAMABIKO JAPAN CO., LTD sells the products to distributors, Zen-Noh (National Federation of Agricultural Cooperative Associations), home improvement retailers, and construction machinery rental companies, etc. Through them, the products are supplied to the end users including farmers/foresters, companies in the construction, civil engineering and iron industries and landscapers.

*For the purposes of unifying the management system and managing business assets in an integrated manner, the company integrated sales subsidiaries, which had been separated by region. The company aims to streamline managerial resources, strengthen its selling capability, and improve customer services.

Furthermore, the Company accompanies dealers to visit end users to understand their needs and utilize the information for product development. <North American market>

ECHO Incorporated Group, one of the Company's subsidiaries, sells the products to The Home Depot (*) and other distributors, through which the products are supplied to the end users such as landscapers, homeowners, farmers/foresters, and companies in the construction/civil engineering industry.

*The Home Depot

The Home Depot, Inc. is the world's largest home improvement retailer and construction products and services. It was established in 1978. Sales in 2016 were US$94,500 million (approx. ¥10.3 trillion) and net income was US$7,900 million (approx. ¥870 billion). It has 2,278 stores in the US, Canada and Mexico. It is listed on the New York Stock Exchange. (Excerpted from the company's website) In the Central and South American market, ECHO Incorporated, one of the Company's subsidiaries, sells the products to the distributors of each country, and then, the products are supplied to the end users through dealers. In Europe, Asia and other areas, YAMABIKO CORPORATION sells the products to the distributors in each country. The overseas dealers display the products by brand, and salesperson conducts person-to-person sales while understanding the needs of the end users. The home improvement retailer also displays the products by type and price. The end users purchase the products based on the needs, budget and image they have from advertisement, etc. (1) Unique production and technological capabilities and vertically integrated production

The most important characteristics and strengths of the Company are the "unique production and technological capabilities and vertically integrated production capabilities". Their mainstay 2-stroke engines that are mounted to the outdoor power equipment are manufactured by an integrated production system solely by the Company from development, procurement of aluminum, molding, parts production, processing to assembly, which is said to be unique anywhere in the world. The power sources for the agricultural machinery and industrial machinery are also engines, but they are mostly procured externally. The Company solves various issues with their unique technologies including iron plating and electric discharge processing. This is resulting in the quality improvement and production capacity improvement of the Company. Specifically, the Company has established the following technologies. <Example 1: Iron plating>

Plating is a surface covering method in which the surface of a metal is covered by a thin layer of another metal. For engine production, inside of the cylinder should be plated to avoid abrasion caused by friction with a piston. The conventional method is to use chrome plating from durability and cost perspectives. However, chrome plating gives negative impact on the environment. Its production efficiency is also low. Therefore, there was an increasing demand for different materials for plating. The Company has been working on "iron plating" since 1978 to reduce environmental load. Initially, they could produce only hundreds per day. However, as a result of improved productivity, enhanced plating precision, and reduction of environmental load, the Company now has the iron plating technology that does not require finish processing. Their technology has drastically smaller environmental load. Furthermore, their daily production capacity increased significantly, reaching thousands. The Company holds 5 patents related to iron plating. <Example 2: Electric discharge processing>

As described above, a 2-stroke engine requires less number of parts and has a simpler structure as compared to a 4-stroke engine. Therefore, it is most suitable for the "handheld" and "backpack-style" outdoor power equipment. However, it releases some fuel mixed gas. In order to respond to the increasingly strict exhaust gas regulations globally, the Company was faced with a challenge to control the flow of the fuel mixed gas for efficient burning. In order to achieve it, the Company explored the production methods to modify the internal shape of the cylinder (by installing a wall between the fuel mixed gas passage and internal shape of the cylinder). A "wall" can be created by die-casting (*), but it requires a horizontal hole to lead the fuel mixed gas to a combustion chamber. With die-casting, it was impossible to create a horizontal hole. It was also difficult to carry out machining due to small space in the chamber. The Company came up with the idea of using "electric discharge processing (*)" to create a form while taking advantage of die-casting. Although electric discharge processing enabled to create complicated forms, it was costly due to long processing time and high electrode consumption. The Company conducted research on processing conditions for a large volume production and developed designs of special electrode form. As a result, it succeeded in producing a large volume of products, by shortening processing time, saving personnel, lowering the cost of electrode and enhancing efficiency. Having obtained three patents related to electrode processing, the Company has established the unique technology that cannot be imitated by other companies.

(*) Die-casting

Die-casting is one of the metal mold casting methods. By injecting melted metal in a metallic mold, a large amount of casting with high precision can be produced within a short period of time. It enables to create a thin product at low cost. (*) Electric discharge processing Electric discharge processing is a machine processing method to remove a part of the surface of a non-processed workpiece through repeated electrode discharge at short cycles between electrode and the non-processed workpiece. It enables to cut out complicated outline on extremely hard steel. While many companies in the world are forced to leave the industry because they cannot address these issues, YAMABIKO CORPORATION continues to make further development as a leading manufacturer. (2) Unique research and development capabilities for each business segment

The Company's capability to address environmental issues is high. The Company possesses one of the highest number of US Environmental Protection Agency (EPA)-accredited engines in the world.Furthermore, not only for outdoor power equipment, the Company also has unique research and development capabilities for the agricultural machinery and industrial machinery. Based on the technological capacities that have been accumulated by KIORITZ and Shindaiwa for many years, the Company is further brushing up the capabilities. (3) Extensive product lineup and expansion of sales network and domestic services network

The Company has an extensive lineup of products that meet various needs of the customers in each of the three business segments. It also currently supplies the products to about 28,000 stores in more than 90 countries across the world. As a result of merging KIORITZ and Shindaiwa, YAMABIKO CORPORATION's product lineup and sales network were further expanded. With the aim of improving the satisfaction level of diversifying users, the company established "Yamabiko Service Shop" inside Japan in 2013, and is operating service systems for maintenance, repair a failure, etc., which are not offered by competitors, throughout Japan. The number of affiliated shops is 411 as of Aug. 2017. (4) Excellent technical support system

The Company also provides excellent technical support in order to enhance credibility of the products and strengthen the relationships with distributors and dealers. It has offered 115 service schools in 15 countries within 2 years from April 2015 to March 2017. (5) High product share

By demonstrating the above-mentioned characteristics and strengths (1) to (4) in an integrated manner, the Company is becoming highly competitive at a global level. For the outdoor power equipment business, the Company has the top market share (more than 30%) in Japan and is ranked high in North America, the largest market.

In the Medium-term Management Plan, the company aims to achieve an ROE of 10% or over in FY December 2019. |

| First Half of Fiscal Year December 2017 Earnings Results |

Sales grew, while operating income dropped.

Sales were 62.6 billion yen, up 2.3% YoY. In North America, the performance of outdoor power equipment was sluggish because the demand season was rainy, while in Japan, the sales of agricultural machinery and outdoor power equipment grew. As the business of YAMABIKO became healthy in Russia and grew in China, the sales in the 2nd quarter marked a record high. Operating income dropped 18.4% YoY to 4.5 billion yen. Sales growth and the yen depreciation contributed to profit, but the unrealized profit for inventory affected profit, and the augmentation of SG&A expenses, including temporary expenses due to irregular accounting period and cost for integrating sales affiliates, was not offset. Ordinary income increased 14.8% YoY to 5 billion yen, because the exchange loss of 1.3 billion yen in the same period of the previous term turned into an exchange gain of 200 million yen, and net income grew 35.3% YoY to 3.6 billion yen, because the provision for product warranties amounting to 500 million yen in the same period of the previous term was not posted this term. Sales and operating income were almost as estimated, while ordinary income and net income exceeded the respective initial estimates and revised ones (announced in Aug. 2017) thanks to the effects of exchange rates.   ◎ Outdoor power equipment

Sales increased 1.2% YoY to 44.4 billion yen.(Japan) Thanks to the effect of the campaign emphasizing the light weight of each product, the sales of mainly trimmers increased, and the sales channels to home improvement retailers expanded, boosting sales further. (Americas) The performance in North America, which is the major market of the company, was sluggish due to the rainy, low-temperature weathers in the first half of the demand season, but the business in Latin America recovered. Sales were nearly unchanged YoY due to the yen depreciation, etc. (Overseas, excluding the Americas) The performance in western Europe was weak, due to unfavorable weathers, the poor harvest of olives, etc., but overall sales increased thanks to the yen depreciation, the recovery in Russia, and sales growth in China.  ◎ Agricultural machinery

Sales grew 7.2% YoY to 11.3 billion yen.(Japan) The sales of sloop mowers and mowers remained healthy. As the demand for pest control machines grew due to unfavorable weathers, the performance of power sprayers was robust, boosting sales. (Overseas) Commodity prices remain sluggish, but sales rose due to the effects of sales promotion.   ◎ Industrial machinery

Sales grew 4.0% YoY to 5.7 billion yen.(Japan) The performance of lighting equipment was stagnant, but the sales of generators were healthy, thanks to the recovery of construction machinery rental and the demand for infrastructure development. The results of welders and engine cutters were also favorable, and sales rose. (Overseas) Generators sold well, increasing sales.  ◎ Others

Sales decreased 10.6% YoY to 1.1 billion yen.

Due to the augmentation of short and long-term debts, total liabilities increased 1,794 million yen from the end of the previous term to 49,653 million yen. Net assets grew 2,079 million yen from the end of the previous term to 49,563 million yen. As a result, equity ratio rose 0.2% from the end of the previous term to 50.0%. The balance of short and long-term debts increased 983 million yen from the end of the previous term to 19,336 million yen.  As the purchase of property, plant, and equipment and intangible assets grew, the deficit in investing CF increased, and the surplus of free CF dropped. The deficit of financing CF shrank due to the augmentation of short and long-term debts. The cash position degraded. |

| Fiscal Year December 2017 Earnings Estimates |

The earnings forecast revised upwardly.

The earnings forecast announced at the beginning of the term was revised downwardly in Aug., and then revised upwardly in Nov. Sales are estimated to be 102 billion yen, up 4.1% YoY, operating income 6.3 billion yen, down 21.0% YoY, ordinary income 6.7 billion yen, down 14.8% YoY, and net income 5.1 billion yen, up 63.0% YoY. The reasons for the revision include the emergence of demand for chain saws for recovery after the landfall of hurricanes in the U.S. and the yen weakening more considerably than expected. (Since two hurricanes hit the U.S. in Aug. and Sep., the demand for chain saws and power generators, as machinery for recovery, grew considerably. The shipment volume of chain saws at a U.S. subsidiary in Sep., which falls on the 3rd quarter, was up 85% YoY.) It is assumed that 1 US dollar = 110 yen, which is unchanged, and 1 euro = 130 yen, up 10 yen from 120 yen in the previous assumption. Although the current accounting period is only 9 months, the dividend amount is to be 35 yen/share, up 5 yen/share from the previous estimate and up 10 yen/share from the previous term. The estimated payout ratio is 28.4%. |

| Regarding 2019 Medium-term Management Plan - Activities in the major market |

(North America)

As mentioned above, this term, sales declined slightly from the previous term due to unfavorable weathers in the demand period. The sales routes of the Home Depot and distributors decreased YoY. Under these circumstances, the company is enhancing the sale to professionals, which is the development target of products of YAMABIKO. The company launched the product series "X Series" for top-grade products that would make professional work more efficient, and implemented the measures for enhancing the support for dealers' sales activities titled "Landscaper Blitz Program." This is the sales program for attracting new medium to large-scale professional clients. The company promotes clients to try its products to realize how excellent they are. The company will intensify the distribution of its products in the professional market, which was the first target when the company entered the North American market. The company plans to release new products mounted with a "global engine" for improving production efficiency and reducing cost by using unified parts, such as trimmers, chain saws, power blowers, and hedge trimmers, from this year. As for new robotic mowers, the company plans to tentatively release the "ECHO" brand for upgrading its brand power in 2018, and start full-scale release in 2019, although it is delayed because of regulations on radio waves. (Europe)

Yamabiko Europe SA, which was founded in Jan. 2017, concentrates on the development of an environment in which distributors can carry out sales activities more easily, and engages in the design of sales measures according to countries and regions, the training of trainers in distributors for brushing up selling and service skills, the collection and analysis of information on dealers, the enhancement of brand popularity, and so on. As selling strategies, the company handles "X Series," products for professional use, like in North America, intensifies the sales of accessories, releases new robotic mowers of the "ECHO" brand in 2018, and so on. In Europe, too, the company will release new products mounted with a global engine. In the European market, where environmental regulations are becoming tighter, the company will meet needs and expand its market share by releasing "Battery Series," including the first chain saws of the company. (Japan)

The measures for expanding its market share are as follows: The company released the lightest models of trimmers and chain saws in Apr. and Sep., respectively. The company cultivated and cemented relations with leading home improvement retailers, including DCM Group, LIXIL VIVA, and Komeri, and then the regular products of YAMABIKO were adopted by major business partners. The full-scale operation of "YAMABIKO JAPAN," which was established by integrating 7 sales companies in Japan, began. While strengthening selling and service skills, the company is streamlining the selling process by unifying the processes of selling agricultural and industrial machinery.  This system was produced by mounting a drone of Yamaha Motor with a spraying device of YAMABIKO. Excellent spraying quality was achieved by the optimal layout of the vertical coaxial rotors and spraying nozzles. Full-scale sale is scheduled at the end of 2018. In addition, the company released new speed sprayers mounted with an automatic spraying mode. As its characteristics, pressure is adjusted automatically according to speed, and it can blow a large volume of air with low noise.  |

| Regarding Yokosuka Plant |

|

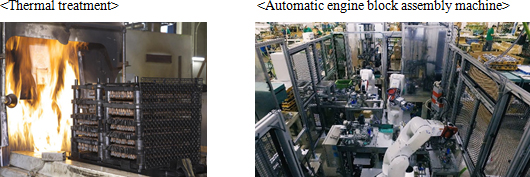

As for two-stroke engines, which are installed in outdoor power equipment, which is the core product of YAMABIKO, the company develops products, procures aluminum, casts it, produces parts, processes them, and assembles them all by itself in an unexampled manner. The company solves various problems with manufacturing with its original technologies, including iron plating and electric discharge processing, and improves product quality and productivity. Its "original production technology and integrated manufacturing system" are attributable to Yokosuka Plant of YAMABIKO. <Outline of Yokosuka Plant> In 1947, it started manufacturing in Urago-cho, Yokosuka-shi, and since 1961, it has been in operation in Natsushima-cho, Yokosuka-shi. Namely, it has been exactly 70 years since it started manufacturing. Inside its premises of about 8,000 tsubo (≒ 26,000 m²), about 400 employees manufacture engine parts, including pistons, cylinders, crankshafts, and crankcases, and assemble them into engine blocks. This plant produced 1.28 million engines in the term ended Mar. 2017. This amount accounts for 46% of the total output of YAMABIKO: 2.79 million engines. It obtained ISO9001 (quality management system) in 1994, and ISO14001 (environmental management system) in 2001.   <Capital investment at Yokosuka Plant> The company currently recognizes this plant as "a production site specializing in engine manufacturing," and is investing in equipment strategically as planned.  "Iron plating" and "electric discharge processing" are YAMABIKO's original technologies polished through activities over many years. (For the details of the two technologies, see the section "Characteristics and Strengths.") <Organizational power that generates originality> The company considers that the above-mentioned originality is derived from its organizational power. YAMABIKO actualizes unrivaled manufacturing, by allowing all staff members of R&D and production sites to share the problems with material research, casting, metal treatment, machining, and assembly, and inducing the organic interaction between "advanced research and production technologies" and "factory competitiveness with accumulated know-how." In addition, the integrated production system ranging from casting to assembly leads to the improvement in the quality and performance of products and stable manufacturing. |

| Conclusions |

|

In the medium term, the processes in Yokosuka Plant are being automated, saving manpower, and the steady improvement in product competitiveness can be expected. We also would like to see when new products, including drones, and robotic mowers, whose development is somewhat delayed, will start contributing to revenue. |

| <Reference1: Regarding "2019 Medium-term Management Plan" > |

|

Outline of "2019 Medium-term Management Plan"

The company set two visions for clearly sharing what kind of company they should aim to develop in the medium to long term.

① Basic policy and vision  ② Key initiatives

In order to actualize the visions set in the above basic policy, the company will take the following key initiatives.

③ Basic policy in each segment

The company will keep further cultivating the market of billboard ads at stadiums of Major League Baseball (MLB) and Major League Soccer (MLS), etc. targeted at homeowners, produce and air commercials for introducing a new corporate image, and conduct sales promotion targeted at professionals. The company will also promote the sales of accessories, which are highly profitable, and utilize sales networks. (Europe) The company will operate "Yamabiko Europe SA," which was renamed in parallel with the strengthening of its selling function in Jan. 2017, on a full-scale basis. Primary measures are to actualize the growth strategies of major distributors, promote the sales of robotic mowers, and strengthen digital marketing. As for robotic mowers, the company will release a new type of evolved mowers. The robotic mower market is growing with an estimated annual growth rate of 20% (for the volume of shipments). At present, the company sells robotic mowers mainly in Europe, but it will actively cultivate the U.S. market, too, while considering that there is a significant business chance there.     ⑤ Regarding the return to shareholders

As the company will keep paying dividends stably and its consolidated financial standing is improving, the company has decided to change the target consolidated payout ratio from "about 25%" for the previous Medium-term Management Plan to "25% or higher" for the new Medium-term Management Plan.

|

| <Reference2: Concerning corporate governance> |

◎ Corporate Governance Report

Last updated: June 29, 2017.

Disclaimer

This report is intended solely for information purposes, and is not intended as a solicitation for investment. The information and opinions contained within this report are made by our company based on data made publicly available, and the information within this report comes from sources that we judge to be reliable. However we cannot wholly guarantee the accuracy or completeness of the data. This report is not a guarantee of the accuracy, completeness or validity of said information and opinions, nor do we bear any responsibility for the same. All rights pertaining to this report belong to Investment Bridge Co., Ltd., which may change the contents thereof at any time without prior notice. All investment decisions are the responsibility of the individual and should be made only after proper consideration.Copyright (C) 2018 Investment Bridge Co., Ltd. All Rights Reserved. |